Characteristics of industrial paint

Features of liquid paint

Among the main measurable characteristics of liquid paint are

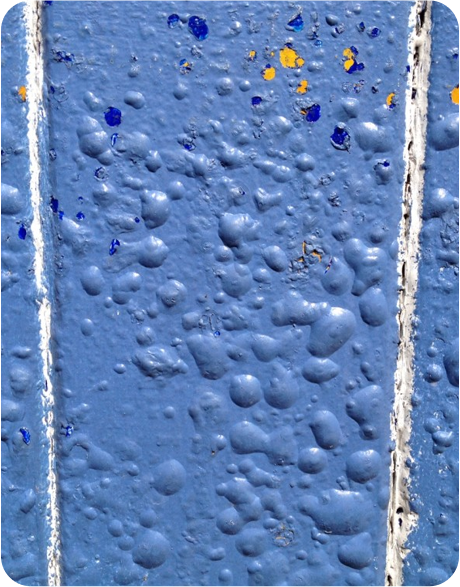

Features of the dry paint film

Once the paint coat is dry, a number of characteristics of the film that has been formed can be determined and assessed.

The thickness deposited will depend on the composition of the paint (solid content) and the way it is applied. Each paint must be applied with the thickness recommended by the manufacturer in the technical data sheet.

Types of industrial paint

It is difficult to classify the different types of industrial paints and coatings in a defining way, since there can be different interpretations based on factors such as their composition, their position in the finish system or even according to the way the paint dries and hardens after application.

Depending on the position in the finishing system

For an industrial paint to fulfil its protective and decorative functions, it is essential to know the particularities of each painting system and process. We can classify the industrial paint according to its position in the application coat:

► Primer

These are the first coats of paint in direct contact with the substrate, highly pigmented and with a low binder content.

Its mission is to serve as an anchor for the following coats of paint and to prevent rusting on metal surfaces by means of the anti-corrosion pigments it contains. Types of primers for industrial paint.

► Intermediate coats of paint

These coats are applied over the primer, generally with the mission of increasing the thickness of the paint system, in order to avoid giving several coats of finish, reducing costs in the application.

The pigment/binder ratio is lower than that of primers but higher than that of finishing paints.

Nowadays, high thickness intercoats are widely used to achieve films of 100 or 200 microns per coat.

► Finishing paints

As the name suggests, they are those that are applied as last coat of the painting system, either to the primer or to the intermediate coat.

They are formulated with a low pigment/binder ratio to achieve the best permeability and strength features. They are usually gloss paints, although there is an increasingly growing demand for satin and matt finishes in the market.